Everything Engineers, Contractors, and Owners Need to Know to Create the Optimal Indoor Pool Environment.

CHAPTER SIX

Reducing energy consumption is an earth-friendly and green focus that also reduces operating costs and monthly bills.

Choice of operating conditions and building envelope should be discussed during the design phase in order to ensure optimal energy consumption and performance. For example, an all-glass structure is going to be expensive to heat and difficult to keep condensation-free in a cold climate.

A natatorium has five major areas of energy consumption:

- Pool water heating

- Dehumidification

- Space heating in winter

- Space cooling in summer

- Outdoor air heating and cooling

OPERATING CONDITIONS

Pool water heating and evaporation rates are always interrelated. Every pound of moisture evaporated to the space is a load to be dehumidified, and it also represents heat lost by the pool water. Approximately 90% of an indoor pool’s annual water heating cost is due to evaporation losses. Every pound of moisture evaporated represents ~1000 Btu of heat lost from the pool water body, and unless a pool is covered, that heat is lost 24/7.

- The warmer the pool water, the higher the evaporation rate.

- The lower the space relative humidity level, the higher the evaporation rate.

- The lower the room temperature (dew point), the higher the evaporation rate.

At the same water temperature, a pool in a room at 78°F 50% RH will evaporate almost 35% more than that same pool in an 85°F 50% RH room.

While the space temperature should be dictated by the owner based on what satisfies their patrons, it is useful to be aware of a few guidelines that can help with energy consumption:

- Maintaining the room air temperature as warm as possible (usually 2-4°F above the pool water temperature) will help reduce evaporation. Most applications don’t want to see air temperatures above 86°F per ASHRAE guidelines; however, indoor pools sometimes go beyond that recommendation, with kids swim schools seeing air as warm as 92°F and some elderly swim programs exceeding that recommendation as well. Reducing the evaporation in turn reduces the pool water heating requirement as well as the dehumidifier size.

- Introducing more outdoor ventilation air than required by code will impact the space RH levels in summer and winter. In winter, the space relative humidity levels will drop below 50%, which increases the evaporation rate and pool water heating requirement.

SEASONAL RH LEVELS

In the summer, the outdoor air tends to be a load, but since it is warm outside, condensation is not a concern. In this case, it is recommended to model the space at 60% RH.

In winter, there is significant risk of condensation, so it is recommended to model the space at 50% RH. The outdoor air in winter almost always is a dehumidification credit, making this easily achievable.

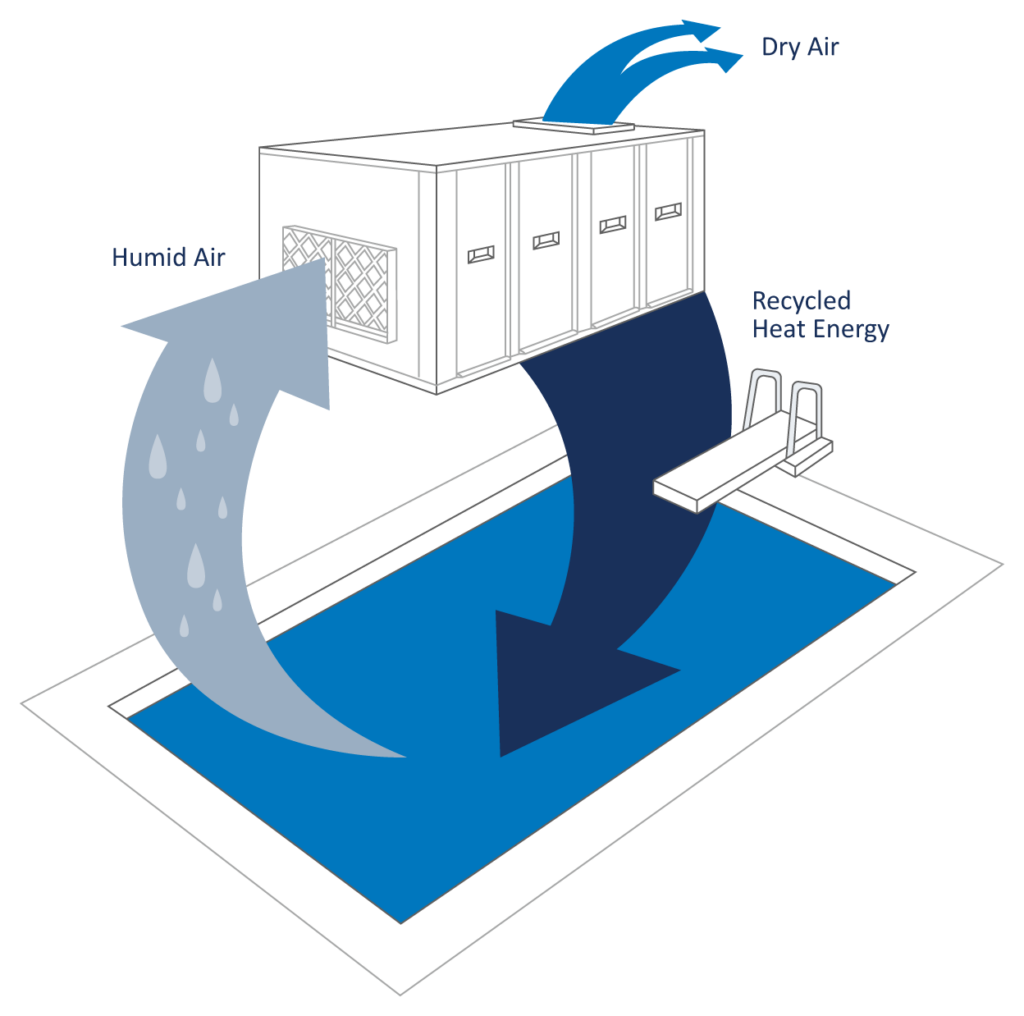

POOL WATER HEATING ENERGY RECOVERY

When using a refrigeration-based approach to control humidity, the dehumidification process captures energy in the refrigerant at the evaporator coil. The latent heat component is essentially the pool’s evaporation. Evaporation represents a significant portion of the pool’s annual water heating requirements. This captured energy can be returned to the pool water to provide free heating (Figure 9).

A dehumidifier with a pool water heating option has an enormous potential for energy savings. This process has an impressive coefficient of performance of 8.

The use of the pool water heating option satisfies ASHRAE Energy Standard 90.1; otherwise, a pool cover is required to meet the standard.

A refrigeration-based dehumidifier can use up to 100% of the compressor hot gas waste heat to heat the pool water and/or reheat the air. Returning this free energy back to the pool water or room air greatly reduces the annual heating costs. During winter, the dehumidifier is capable of providing 100% of the pool’s water-heating requirement.

The mechanical refrigeration system approach to controlling the environment in a pool is a unique use of the refrigeration system. The evaporator controls the humidity, while the compressor hot gas can be used to heat the pool water and/or room air simultaneously. Traditional air conditioning systems merely send the compressor hot gas outdoors to a condenser or cooling tower and do not tap into this heat source.

Due to increased energy savings, the pool water heating option typically pays for itself in less than one year.

Table 4 highlights the annual contribution towards water heating from the dehumidifier while operating in cooling mode. A pool with a 50 lb/hr evaporation rate and a cooling season of 2,000 hours would realize an annual savings of $2,350 if the primary source of pool water heating was an electric heater.

Calculations are based on the following: 1000 Btu/lb latent heat of vaporization. Gas: $0.60 per 100,000 Btu, efficiency = 75%. Electricity: 8¢ per kWh.

Most pools require an auxiliary pool water heater. When the dehumidifier is not able to provide full water heating, it can control the auxiliary heater.

TABLE 4 – ANNUAL WATER HEATING SAVINGS FROM POOL HEATING OPTION

| ANNUAL SAVINGS FROM POOL WATER HEATING OPTIONS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cooling Season | Heat Source | Average pool evaporation (lb/h) | |||||||

| 20 | 30 | 40 | 50 | 100 | 150 | 200 | 300 | ||

| 4000 hours | Gas | $640 | $960 | $1280 | $1600 | $3200 | $4800 | $6400 | $9600 |

| Electricity | $1880 | $2820 | $3760 | $4700 | $9400 | $14100 | $18800 | $28200 | |

| 2000 hours | Gas | $320 | $480 | $640 | $800 | $1600 | $2400 | $3200 | $4800 |

| Electricity | $940 | $1410 | $1880 | $2350 | $4700 | $7050 | $9400 | $14100 | |

FIGURE 9: THE ENERGY CYCLE

SPACE HEATING

As with every other room being designed, the cooling and heating load calculations should be performed for the natatorium. That is the only way to ensure the specific heating and cooling requirements are met. The room air temperature of an indoor pool facility is generally 10-15°F warmer than a typical occupied space, so the heating requirement per square foot of a natatorium will be considerably higher than a traditional room. Outdoor air must be included in load calculations as it often represents up to 50% of the heating load.

SPACE COOLING

Most patrons prefer buildings with year-round temperature control. Even though the space is generally 10-15°F warmer than a typical room, most patrons would find it objectionable to be in a space that has no cooling at all.

Space cooling is a free byproduct from packaged dehumidifiers and chilled water systems. These systems can provide year-round temperature and humidity control. They dehumidify by cooling the air below its dew point and condensing moisture at the cooling coil. If the cooling load exceeds the standard output of a dehumidification unit, a larger unit with compressor staging is often specified.

OUTDOOR AIR, EXHAUST AIR, AND ENERGY RECOVERY

Outdoor ventilation air is essential for maintaining good IAQ in the pool and is a code requirement. The natatorium needs to be maintained at a slight negative air pressure, so warm “energy rich” air needs to be exhausted.

Outdoor air must be cooled and dehumidified in the summer and heated in the winter. In cold climates, outdoor air has the biggest impact in winter where it reduces the space relative humidity levels and represents a significant portion of the natatorium’s heating requirement. Outdoor air in winter may need to be heated 100°F to become neutral to the space temperature. In southern regions, the outdoor air introduces a lot of moisture and increases the dehumidification load.

The designer has several energy issues to consider:

- Introducing more outdoor air than codes require is not recommended:

– In winter, it will increase space heating and pool water heating costs significantly.

– Too much outdoor air in winter can also lower the relative humidity levels to uncomfortable levels for the patrons.

– In summer, it can introduce so much additional moisture that larger equipment could be needed.

- Warm “energy rich” air is required to be exhausted from the space to maintain negative pressure and good IAQ.

Energy recovery from the “energy rich” exhaust air should be considered.

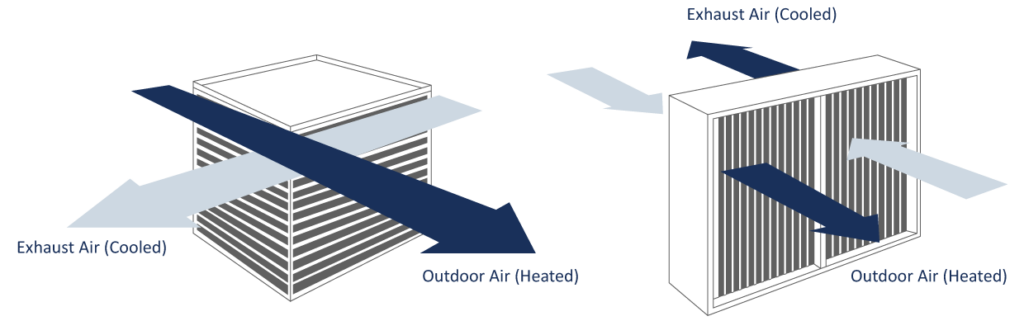

FIGURE 10: HEAT EXCHANGE

Air-to-air heat exchangers are available for both sensible heat recovery and total energy recovery. Sensible-only devices are used in natatoriums. All sensible recovery devices are effective, but some are better suited to provide a cost-effective solution. Figure 10 highlights two examples. There are several questions that must be answered to determine which heat recovery approach is best suited for a particular facility:

- Is the installation in a cold climate application?

- Does the outdoor ventilation air need to be conditioned in order to avoid condensation when blended with the room air in summer and winter?

- Are the outdoor ventilation air and exhaust air streams within close proximity to each other?

- What is the return on investment?

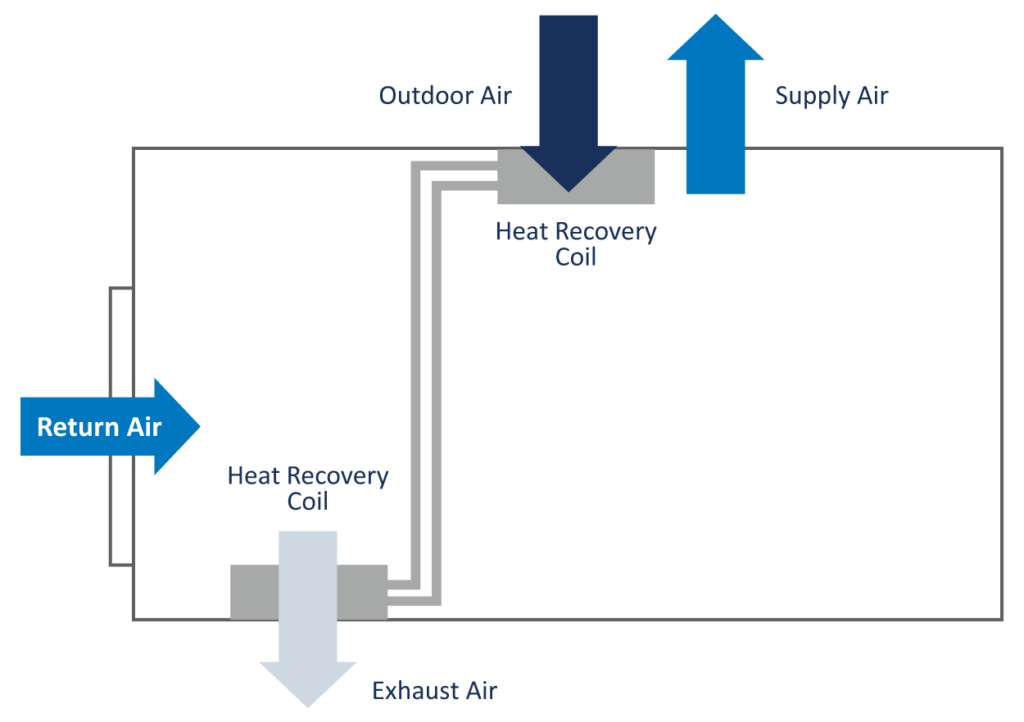

GLYCOL RUNAROUND LOOP

Heat recovery is generally packaged as part of a dehumidifier when outdoor or rooftop installations are specified. Figure 11 shows a schematic of a recommended glycol runaround loop heat recovery method. This heat recovery option can be packaged seamlessly within the dehumidifier or remotely installed in the ductwork. The plate heat recovery devices in Figure 10 require special and complicated air paths within the unit. This increases the unit size and cost and also has a large airside pressure drop, which increases blower motor sizes and operating costs.

The annualized energy recovery of the glycol runaround loop outperforms any other form of heat recovery.

FIGURE 11: PACKAGED HEAT RECOVERY

The glycol runaround loop approach to heat recovery offers the best performance and design flexibility in the smallest cabinet possible. This heat recovery coil set fits directly onto the outdoor air and exhaust air openings already provided on the unit without increasing the cabinet size. They are also easily sized to meet the specific requirements of the facility. The result is a compact, cost-effective heat recovery option that outperforms other technologies. The compact nature of this design results in lighter-weight cabinets compared to units integrating plate heat recovery technology. This is an important consideration on applications where roof loads are a concern.

The glycol runaround loop approach is well suited for the corrosive indoor pool environment as it offers superior corrosion protection compared to plate heat recovery devices.

The glycol runaround loop approach is also well suited for cold climate applications. On the coldest winter days, when heat recovery is needed the most, other heat recovery devices require the bypassing of air to prevent the device from freezing. However, the glycol approach does not present this risk.

The introduction of the heat recovery coils into the existing air streams offers a substantially lower overall airside pressure drop compared to units with dual air paths and complicated internal air patterns. This configuration offers the end user the lowest possible operating cost while providing the best possible heat recovery effectiveness.

A heat recovery option in a cold climate application will typically pay for itself after one year due to increased energy savings.

The savings are noteworthy even in a mild climate, where these devices generally pay for themselves in two to three years.

TABLE 5 – ENERGY RECOVERY CALCULATION

| WEATHER DATA | ||

|---|---|---|

| City | Average °F T1 | Winter °F T2 |

| Atlanta | 61 | 17 |

| Boston | 51 | 6 |

| Buffalo | 43 | 2 |

| Chicago | 51 | -8 |

| Dallas | 65 | 18 |

| Denver | 50 | -5 |

| Detroit | 49 | 3 |

| Minneapolis | 45 | -16 |

| Indianapolis | 52 | -2 |

| Nashville | 60 | 9 |

| New York | 54 | 11 |

| Oklahoma City | 60 | 9 |

| Pittsburgh | 50 | 3 |

| Portland, OR | 53 | 17 |

| Salt Lake City | 52 | 3 |

| Seattle | 51 | 20 |

| St-Louis | 55 | 2 |

| Toronto | 46 | -5 |

| HEAT RECOVERY SAVINGS (Q) ANALYSIS | |||

|---|---|---|---|

| Pool Location | Atlanta | ||

| T1 | Average Outdoor Temperature | 61 | °F |

| T2 | Winter Design Temperature | 17 | °F |

| T3 | Indoor Design Temperature | 85 | °F |

| V | Outdoor Air Volume | 3500 | CFM |

| N | Occupied Hours | 12 | Hours |

| ER | Electric Rate: | 0.06 | $/kW |

| GR | Gas Rate: | 0.65 | $/CCF |

| GE | Gas Heating system efficiency: | 60 | % |

| Space Heating by: | GAS | ||

| HE | Heat Recovery Efficiency | 50 | % |

| Q | {t3-T1} x 1.08 x V x {8760*N/24} x GE | 190400 | MBH |

| ANNUAL SAVINGS FROM HEAT RECOVERY DEVICE | |||

| $ | {Q x $/CCF} / HE | $2,062 | |

| REDUCTION IN PEAK HEATING | |||

| Q1 | {T3-T2} x 1.08 x V x HE | 126,000 | Btu/h |

FAN ENERGY AND DUCT DESIGN

Air movement and circulation is a significant energy component in indoor pools. It can be 50% of the electrical consumption and potentially more if the duct static pressures are high or the fans are inefficient.

The supply fan(s) on a pool unit operate 24/7, and the operating costs can increase with a high-pressure duct.

On a 32,000 CFM system, going from 1 to 3” ESP raises fan BHP from 24.5 to 40.5. This equates to roughly 12kW 24/7/365 of extra energy usage. With an average electrical supply cost of $0.12/kWh, that is an extra expense of roughly $12,600 per year in running costs – or roughly $200,000 over the life of the machine. These numbers do not even factor in other possible expenses such as electrical service upgrades or additional capacity charges from the local utility.

Considerations during the design phase and equipment selection can help minimize the energy footprint. A ‘big picture’ look at the total cost (installation and operation) of a project is important in the design phase. Saving costs upfront on an inefficient ductwork design may actually drive up overall operating costs significantly.

Most equipment today is built with direct drive plenum fans. Belt-driven fans can consume 25% more energy, and that can result in a large operating cost penalty over the lifetime of the equipment.