Everything Engineers, Contractors, and Owners Need to Know to Create the Optimal Indoor Pool Environment.

CHAPTER FOUR

Good indoor air quality must be a primary goal for all. If it is a top concern, it will get the attention it needs and deserves.

The definition of acceptable indoor air quality for an indoor pool is something the Council for the Model Aquatic Health Code’s (CMAHC) research is trying to define for North America. Currently, there is no definition regarding what chemical levels are acceptable before having a negative impact on human physiology.

The World Health Organization (WHO) has established a guideline of 0.5 mg/m3 for gas-phase NCl3 (trichloramine) concentration in pools. A slightly more stringent value of 0.3 mg/m3 was suggested by a research group from Belgium. A possible outcome of the project described herein is identification of a different guideline for gas-phase NCl3 concentration, but for now, most recognize the need to stay under 0.5 mg/m3.

Part of CMAHC’s research is to find a means to measure trichloramine levels with commercially available sensors in HVAC systems. Currently, there are no viable trichloramine sensors that can be used in HVAC, so the research is hoping to find a suitable replacement, perhaps similar to VOC or CO2 levels. Once that is established, HVAC system control strategies will be able to adjust based on the chemical levels in the space. While this can have an impact on the IAQ, it will always be reactive to the chemicals already being off-gassed. Addressing water chemical levels directly will have a more immediate impact on IAQ because fewer chemicals will off-gas. Maintaining optimal chemical levels should always be the focus when trying to achieve the best possible IAQ.

Designers that follow ASHRAE Handbook guidelines, as well as those recommended in this guide, should have every expectation of a great space condition and a pleasant indoor pool experience. There are steps a design engineer must take to minimize the chances that a patron experiences discomfort or ill health effects. There are many factors that impact the IAQ in a natatorium. These include pool water chemistry problems, inadequate outdoor air, air stagnation, poor air distribution, high humidity, facility maintenance and operation, as well as occupant/swimmer behavior (urine in pools is responsible for 50% of chemical issues).

Four key factors having the most direct impact on indoor air quality are under the control of the design engineer:

- Poor air distribution – no airflow in the breathing zone

- Air change rate

- Outdoor air ventilation

- Exhaust air – chemical source capture

Factors that have a significant impact on IAQ but are not under the control of the HVAC design engineer are pool water chemistry, maintenance, operation, and patron behavior. It is vital that these are addressed by the facility operator.

BREATHING ZONE

The single most important focus of the HVAC design is to provide adequate supply air down into the breathing zone. The supply air from the HVAC system has been conditioned and filtered with outdoor air blended in. It is the best quality air the system has to offer. When supply air is delivered down into the breathing zone, patrons will enjoy the best possible air quality.

A properly designed facility will adequately control and remove chloramines while providing the treated and conditioned air to where it is most needed – into the breathing zone and deck area.

AIR CHANGE RATE

ASHRAE recommendations for proper volumetric supply air changes per hour are important to ensuring that the entire room will see air movement. Stagnant areas must be avoided, as they will be prone to condensation and air quality problems.

Short circuiting between supply and return air must also be avoided as it significantly reduces the actual air changes within the space and the overall effectiveness of the HVAC system.

ASHRAE recommends:

- 4-6 volumetric air changes per hour in a regular natatorium

- 6-8 volumetric air changes per hour in spectator areas

A quick calculation will determine the supply air requirement:

- Supply air required (CFM) = room volume (ft3) x desired air changes / 60

The room volume determines the amount of supply air a space requires.

OUTDOOR VENTILATION AIR

The amount of outdoor air to be introduced to the facility is determined by local codes. Most codes adopt ASHRAE Standard 62. Outdoor air is critical towards diluting airborne chemicals and maintaining good indoor air quality.

Facilities that introduce outdoor air per ASHRAE Standard 62 and have proper/effective air distribution will have outstanding IAQ.

- More outdoor air than required by ASHRAE Standard 62 is not required for good IAQ if the air distribution is done well (except for indoor water and splash parks).

- Outdoor air requires a significant amount of heating energy in the winter and must be included in heat load calculations.

- Heat recovery should be considered between the exhaust air and outdoor air streams.

- Introduce the outdoor air at the factory-provided intakes on the air handlers.

- Locate outdoor air intakes away from sources of airborne contamination, such as exhaust fans or plumbing vents.

- The outdoor air may need to be preheated to 65°F if more than 35% of the total airflow is outdoor air or if the winter design temperature is below 10°F.

- A certified air-balancing contractor must balance the system airflow.

All air handlers for indoor pools must be equipped with an outdoor air connection, filter, two-position motorized damper, and balancing damper.

EXHAUST AIR

ASHRAE recommends the room be maintained at 0.05-0.15” WC negative pressure relative to surrounding spaces.

10% more exhaust air than outdoor air is a good rule of thumb.

More exhaust air than recommended by ASHRAE will not reduce or stop moisture migration through the building envelope to the outdoors in cold weather. Vapor migrates based on vapor pressure differential. There is effectively a 10” WC pressure differential between indoors and outdoors on cold winter days. There is no amount of negative airside pressure that can be added to a space to stop vapor migration. To prevent this, vapor retarders must be placed in appropriate locations throughout the entire building envelope.

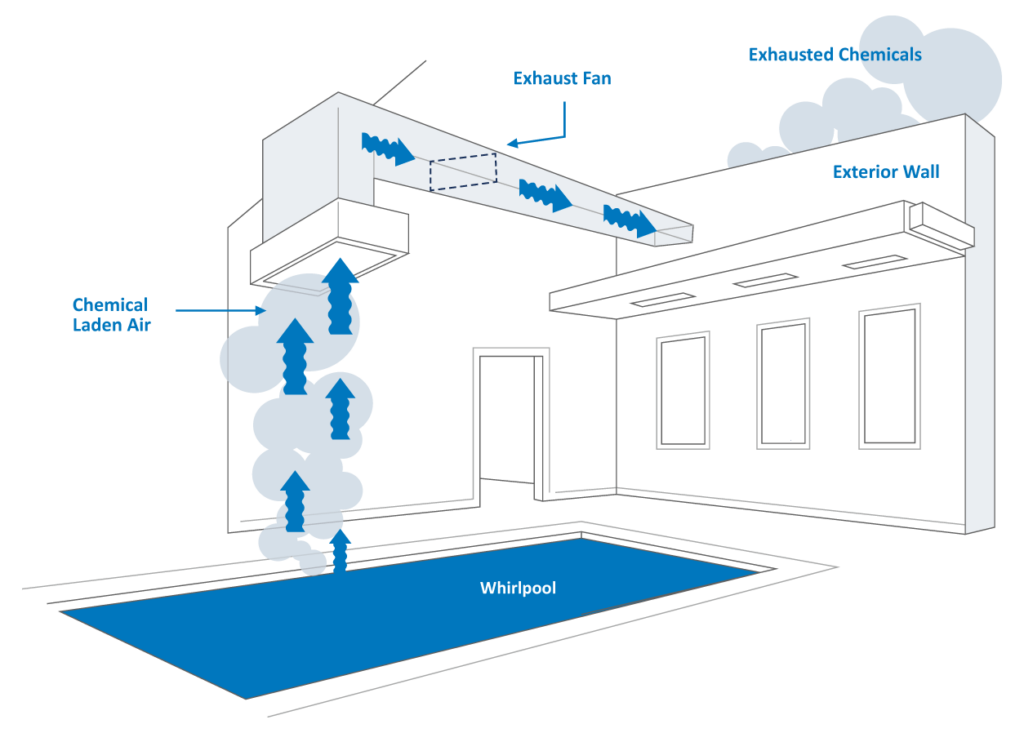

Figure 3 illustrates how the strategic location of the exhaust grille can also significantly improve the air quality in the space. An indoor spa or whirlpool should have the exhaust air intake grille located directly above it. This source captures and extracts the highest concentration of pollutants before they can diffuse into the space and negatively impact the room air quality.

FIGURE 3: EXHAUST AIR

If the Evacuator is being used, it addresses the exhaust air requirements of the space while providing a terrific secondary HVAC benefit. Since it exhausts directly from the water surface, that air gets replaced by air from the space. This enhances the breathing zone by helping draw air down all the way to the water and deck surface.

POOL WATER CHEMISTRY

If there are no chemicals off-gassing, there is no air quality issue. All efforts towards minimized chemical off-gassing in the design and operation of the pool will directly impact the IAQ. Pool water chemistry and facility operation are key variables impacting IAQ that are not generally under the control of the design engineer.

Good pool water chemistry is critical in order to achieve high levels of human health and comfort. Maintaining ideal pool water conditions also ensures the best possible indoor air quality and optimal performance from the mechanical system.

There are new technologies available to help with water chemistry and chloramine management, such as the Evacuator system and ultraviolet (UV) light treatment systems.

CHLORINE SMELL

It is a common misconception that a strong chlorine odor is caused by too much chlorine in the water. The odor is actually caused by chloramines (combined chlorines) off-gassing from the pool water surface.

Chloramines are formed in the pool water when there is insufficient free chlorine in the pool to address the nitrogen-containing compounds brought into the pool water by the swimmers. These nitrogen compounds are naturally occurring and contained in sweat, urine, body oils, and other proteins that get released into the pool water. If the introduction of these nitrogen compounds outpaces the introduction of free chlorine, the chlorine combines with the nitrogen compounds rather than fully oxidizing them.

The chloramine levels increase in the water, resulting in an increase in chloramine off-gassing, which creates the odor of chlorine in the room. There are three different types of chloramines that can form: monochloramine, dichloramine, and trichloramine. Trichloramine is the most volatile and will off-gas most quickly.

Off-gassed chloramines have a strong attraction to the airborne humidity and will combine with moisture in the air. Consequently, any condensation of the space humidity will become corrosive.

SOURCE CAPTURE CHEMICAL EXHAUST

A very effective method of chloramine control is to source capture them off the water surface and exhaust them before they have a chance to become an IAQ problem. The Evacuator system was designed for exactly this purpose. The result is top notch air quality, even on retrofitted systems.

Ultraviolet light treatment of pool water has shown to have a very positive impact on the water chemistry and can help significantly reduce chloramines (if not eliminate them entirely). This approach to water treatment is gaining popularity, and as positive data continues to be released, should become the norm.

HUMIDITY AND CORROSION

Any condensation of the space humidity will become corrosive. It is critical that the space humidity levels be controlled to prevent condensation, as it will damage the building and mechanical system.

By design, indoor pool environments are warmer and, as a result, have higher dew point temperatures compared to traditional spaces.

Engineers and architects must understand the consequences of moist corrosive air and pay special attention to its potential impact on the entire HVAC system and building envelope.

It is a best practice to ensure that all electrical components are located in a separate mechanical vestibule, protected from the pool air stream. All components in contact with the pool air stream should be protected with the best possible corrosion resistant paints, coatings, and materials available.